LASER HEAT TREATMENT SOLUTIONS

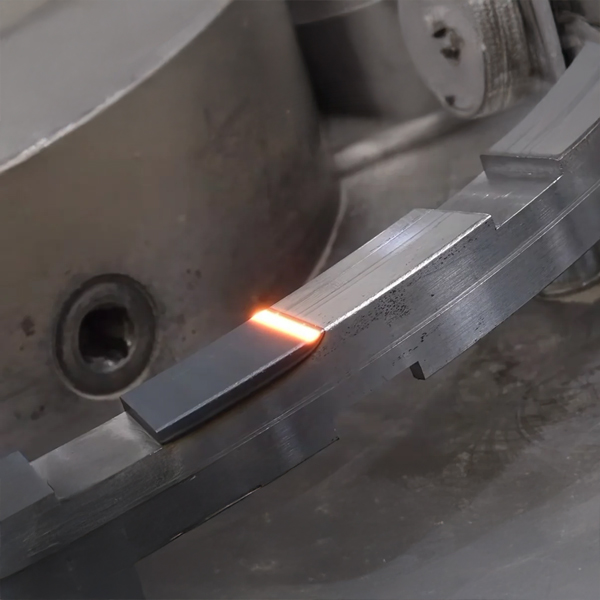

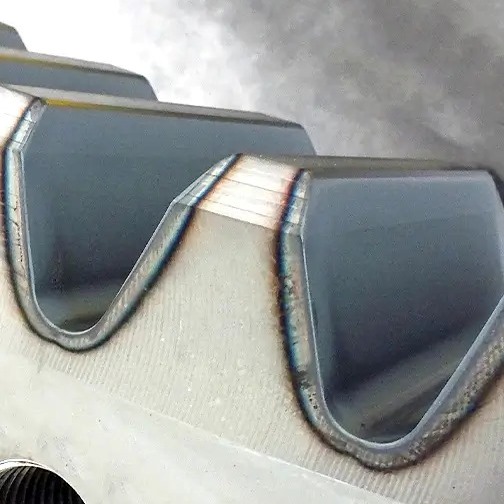

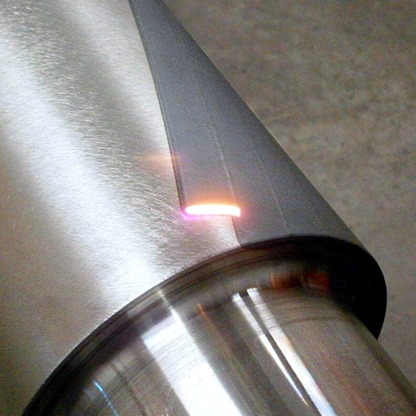

Tajdid Manufacturing Company provides advanced Laser Heat Treatment Solutions that enhance surface hardness, wear resistance, and fatigue strength of critical components with pinpoint precision and minimal distortion. This cutting-edge thermal process utilizes focused laser energy to selectively heat the surface layer of a metal component above its transformation temperature, followed by rapid self-quenching through the part’s thermal mass. The result is a hardened martensitic microstructure that significantly improves the performance and lifespan of the treated part.

Unlike conventional heat treatment techniques, such as flame, furnace, induction, or carburizing methods, laser heat treatment offers unmatched localization, accuracy, and repeatability without the need for liquid quenching or extensive post-processing.

Benefits of Laser HEAT TREATMENT

- Cost Efficiency.

- Self-Quenching.

- No post processing is required.

- Minimal Distortion.

- Deep Case Hardness up to 1.5 mm.

- Consistent Temperature Control .

- Enhanced Wear and fatigue Resistance.

- Selective hardening both is depth and location.

Laser Heat Treatment is extensively used to improve the performance of gears, bearings, shafts, industrial molds and dies, and others, ensuring higher efficiency and superior product quality across various sectors.