TECHNOLOGY ADVATAGES

Tajdid Manufacturing Company leverages Laser Metal Deposition (LMD) technology to deliver precision-driven, cost-effective, and sustainable solutions for remanufacturing and surface enhancement.

The core advantages of LMD include:

- Technical Advantages.

- Economic Advantages.

- Environmental Advantages.

This combination of advantages makes LMD the preferred choice for industries seeking reliable, high-performance restoration and enhancement services. Each advantage is detailed in the sections below to provide a deeper understanding of how LMD can strengthen your operations.

TECHNICAL ADVANTAGES

Laser Metal Deposition (LMD) offers unmatched precision and process control, making it ideal for restoring and enhancing critical industrial components. With superior metallurgical bonding and minimal thermal impact, LMD ensures durability without compromising the integrity of the base material.

- Superior Coating Quality: LMD achieves metallurgical bonding with the base material, resulting in coatings with high ductility, minimal porosity, and excellent resistance to wear, corrosion, impact, bending, and thermal stresses.

- Extended Component Life: Components treated with LMD exhibit superior wear, corrosion, heat resistance and surface hardness, dramatically increasing their operational lifespan and performance under demanding conditions.

- Material Versatility: LMD is compatible with a wide range of materials, including carbon steels, stainless steels, duplex steels, nickel-based alloys, cobalt-based alloys, and iron-based alloys and others, offering customized solutions for diverse industrial needs.

- Minimized Heat-Affected Zone (HAZ): The highly localized energy input of LMD reduces the heat-affected zone, preserving the base material’s mechanical properties and microstructure, and maintaining overall component integrity.

Geometry Restoration: Enables repair of complex geometries and high-value parts that would otherwise require full replacement.

- High Precision and Process Control: LMD delivers exceptional precision in material deposition, ensuring accurate coating thickness, targeted area coverage, and minimal material waste, reducing the need for extensive post-processing.

Laser Metal Deposition (LMD) distinguishes itself from traditional surface enhancement and repair techniques through next primary technical advantages:

Full Metallurgical Bond

Unlike conventional methods, LMD creates strong metallurgical bonds with high ductility, low dilution, superior adhesion, and minimal porosity, ensuring exceptional wear, corrosion, thermal, and degradation resistance.

Minimal Heat Input

LMD allows highly controlled material deposition with minimal heat-affected zones, preserving the base material’s mechanical properties and minimizing distortion, a critical advantage over traditional welding or thermal spraying.

Material Versatility

LMD supports a wide range of material combinations and complex geometries, offering tailored solutions for diverse industrial needs, where traditional methods often face limitations.

DELIVERING SUPERIOR PERFORMANCE WITH ENHANCED STRUCTURAL INTEGRITY, LONGER SERVICE LIFE, AND EXCEPTIONAL RESISTANCE TO DEMANDING OPERATIONAL CONDITIONS.

ECONOMIC ADVANTAGES

Laser Metal Deposition (LMD) offers significant cost savings by reducing the need for part replacements, minimizing waste, and accelerating turnaround times. The technology is particularly valuable for industries where downtime is costly and components are expensive or custom-engineered.

- Reduced Replacement Costs: By enabling high-quality repairs and surface restoration, LMD significantly reduces the need for full component replacement. This approach lowers capital expenditures and maximizes the return on investment for expensive machinery and equipment.

- Minimized Downtime: The precision and speed of the LMD process allow for faster turnaround times compared to traditional repair and manufacturing methods. Shorter repair cycles help minimize operational downtime, directly improving productivity and reducing lost revenue.

- Lower Material Waste: LMD’s controlled material deposition ensures that only the necessary amount of material is used, minimizing waste. This efficiency reduces raw material costs and supports more cost-effective manufacturing and maintenance practices.

- Lower Inventory Requirements: LMD reduces the need to maintain extensive inventories of spare parts by enabling localized, on-demand repairs. This minimizes warehousing costs and ensures faster access to critical components when needed.

- Extended Asset Life: Enhancing the durability and performance of critical components translates into fewer maintenance cycles, less frequent part replacements, and lower lifecycle costs. Companies can operate equipment longer without incurring significant repair or replacement expenses.

- Energy and Resource Efficiency: Compared to traditional welding and coating methods, LMD consumes less energy and fewer consumables, contributing to lower operational costs over time while maintaining high quality and performance standards.

OPTIMIZING RESOURCE UTILIZATION AND MAINTENANCE STRATEGIES TO ACHIEVE SIGNIFICANT COST SAVINGS, REDUCED DOWNTIME, AND GREATER ASSET VALUE OVER TIME.

ENVIRONMENTAL ADVANTAGES

Laser Metal Deposition (LMD) aligns with global sustainability goals by enabling resource efficiency and reducing the environmental impact of manufacturing and maintenance. At Tajdid, we are committed to supporting a circular economy and reducing industrial waste through responsible technology deployment.

Lower Carbon Footprint: Energy-efficient process compared to conventional manufacturing.

Waste Reduction: Precision deposition generates minimal scrap and avoids excess machining.

Material Conservation: Optimized use of critical and high-cost materials supports long-term resource availability.

Sustainable Remanufacturing: Promotes reuse and life-cycle extension of components, reducing landfill waste and production emissions.

Eco-Friendly Alternatives: Serves as a safer, more sustainable solution to hazardous processes such as hard chrome plating.

SUPPORTING RESPONSIBLE MANUFACTURING PRACTICES BY EXTENDING COMPONENT LIFE, CONSERVING RESOURCES, AND MINIMIZING THE ENVIRONMENTAL IMPACT OF INDUSTRIAL OPERATIONS.

Why Laser Metal Deposition (LMD)?

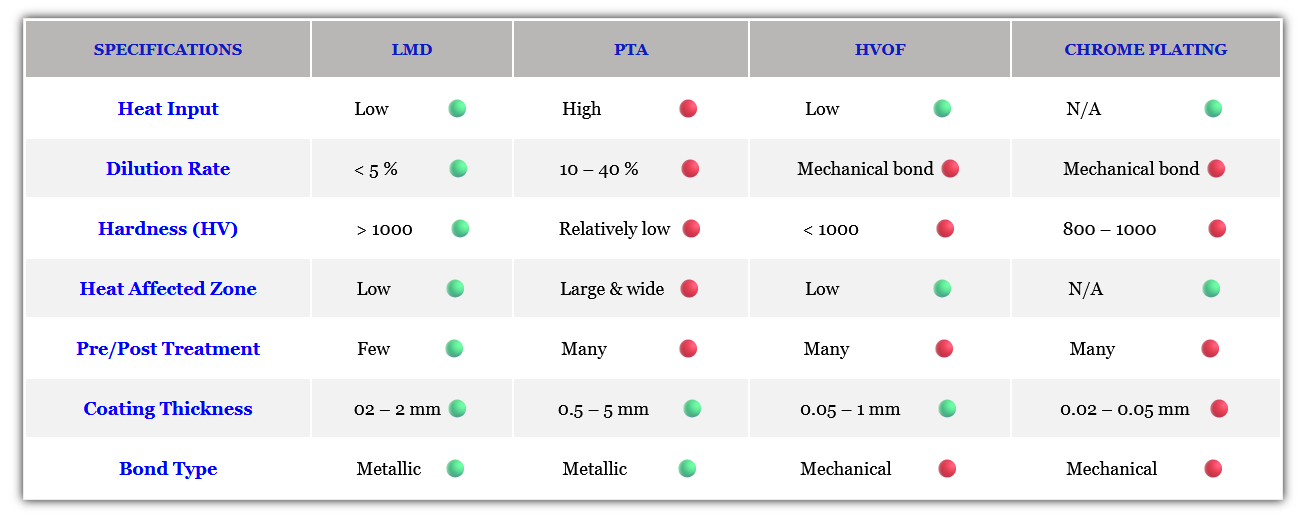

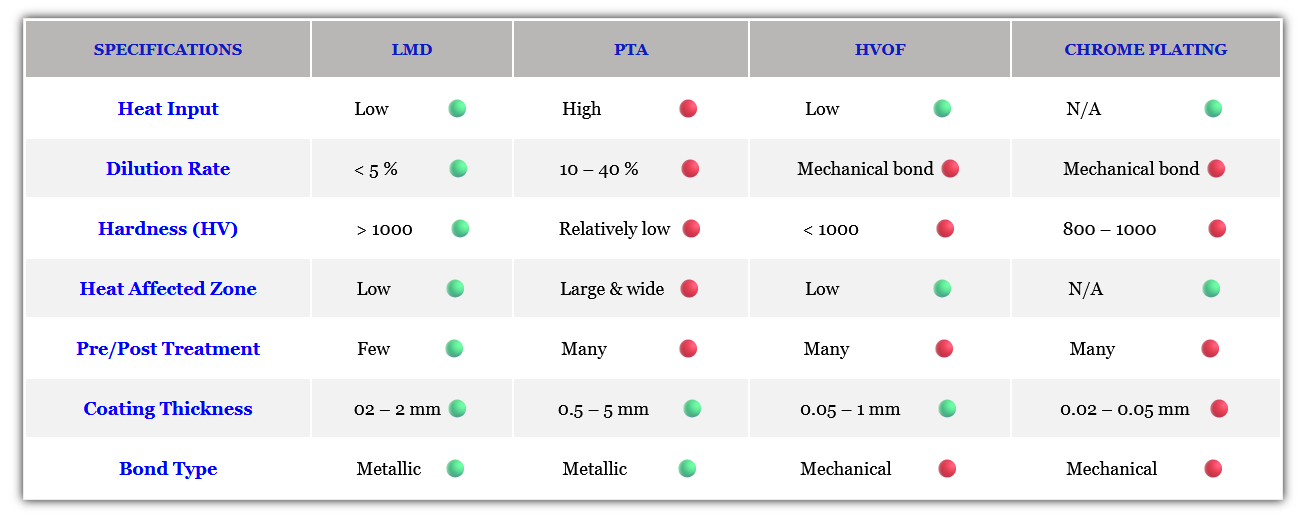

Laser Metal Deposition (LMD) is an effective solution for restoring high-value industrial components due to its precision, efficiency, and cost-effectiveness. Unlike traditional methods, LMD directly applies high-performance alloys to damaged areas, often exceeding original specifications. It operates with low heat input, reducing the risk of distortion and maintaining material strength while ensuring tight dimensional tolerances. LMD also creates a strong metallurgical bond with minimal porosity and reduces the need for extensive post-treatment processes, making it a superior choice compared to Plasma Transferred Arc (PTA), High-Velocity Oxy-Fuel (HVOF), and Chrome Plating.